Electronics Design at RedRidge

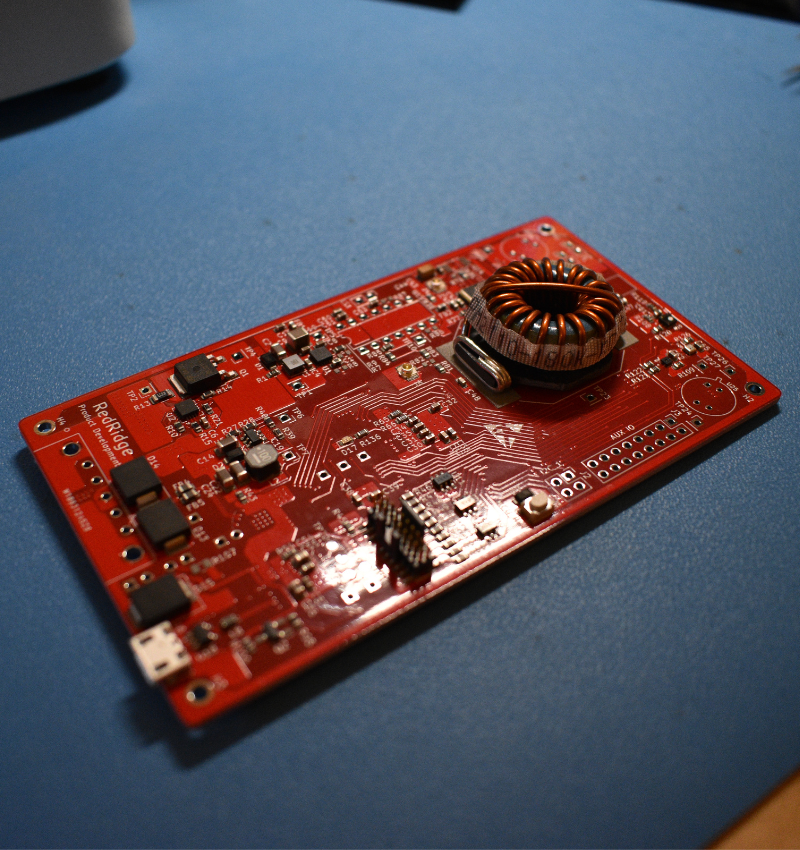

Electronics design has always been our core focus, and Redridge develops electronic hardware for the most challenging applications in the aerospace and medical device industries. From radiation hardened space flight hardware to mass produced consumer electronics, we can design high performance, reliable, hardware to meet your requirements and set your company’s product apart.

Our clients come to us for our experience taking electronics from concept to real production, and our ability to integrate with their other in-house teams (mechanical designers, software engineers, production teams, etc.). Reliably bringing hardware to market requires a process-driven approach, and the discipline to establish and test against concrete technical requirements. It also requires deep experience with current compliance requirements and manufacturing processes to avoid getting stuck in the prototype phase. RedRidge’s electronic product design team brings that and more.

Our electronics development lab in Boulder Colorado serves some of the most technically advanced companies in the rocky mountain region and beyond. And we continue to invest in expanding our in house test capabilities to meet the needs of rapid development programs, adding in-house EMI/EMC compliance pre-screening, ESD testing, cyclic thermal & environmental testing, and more.

RedRidge’s electronics design services benefit from our extensive in-house capabilities, including: PCB Layout, BoM & Supply Chain Strategy, Firmware Development, and Compliance Testing Support.

IoT & Wireless Devices

With the explosion of Internet of Things (IoT) applications, RedRidge has designed a significant amount of IoT device hardware, including one of the very first commercial deployments of the Bluetooth Mesh protocol outside of the smart lighting market, which required working hand in hand with Silicon Lab’s Bluetooth stack development team.

RedRidge regularly develops IoT hardware for applications in battery powered wearables, industrial monitoring, smart homes, smart cities, and civil infrastructure monitoring. We have deep experience designing with Silicon Lab’s Gecko series wireless SoCs, Nordic Semi’s NRF52 & -54 series SoCs, Texas Instrument’s SimpleLink SoC family (CC1352, etc.), and many more multiprotocol wireless SoCs.

In addition to IoT edge devices, RedRidge also develops IoT gateways and edge routers. Gateways are required by many of the popular IoT wireless network protocols, and are typically an embedded Linux system with one of the IoT wireless SoCs acting as a tethered network co-processor (NCP), and a built in WiFi, cellular, or satellite modem providing WAN uplink.

The typical hardware design priorities for IoT products are: reliable and safe battery power systems (frequently with solar PV power), extremely high power efficiency to achieve long battery life, good RF range performance, hardware security features, over-the-air (OTA) update capability, small PCB form factor, and low cost. Key compliance requirements are typically FCC section 15 intentional radiator certification, and UL/CE internal lithium battery certifications. RedRidge delivers IoT hardware that excels on all these fronts, and has the experience to help your product avoid common IoT device pitfalls such as enclosure level antenna interactions, self interference, and battery protection challenges.

Power Electronics

RedRidge is lucky to count several power electronics specialists among our design staff, who allow us to tackle even extremely challenging power electronics designs. We have experience designing converters and input protection stages for challenging on-vehicle applications including automotive bus-powered devices, aircraft systems interfacing to raw turbine power, and spaceflight power systems.

We also regularly design & develop small high efficiency power systems for battery powered devices, as well as the associated battery power systems such as cell protection, charge controllers, USB Type-C PD interfaces, battery fuel gauges, multi-cell charge balancing, and state of health monitoring. RedRidge also regularly develops solar PV power systems, and can help maximize your product’s charging performance with high-efficiency maximum power point tracking (MPPT) designs.

RedRidge has specific experience in designing high power density converters using the latest developments in high bandgap semiconductor devices, namely recent improvements in Gallium Nitride (GaN) and Silicon Carbide (SiC) MOSFETs. These devices offer massive power density advantages over traditional MOSFETs, but impose tighter requirements on gate drive and transient suppression circuits.

We also provide debug and testing support services for existing in-process power electronics designs which are facing challenges with conducted/radiated noise, transient response performance, thermal margin, or control stability. If your team has a particularly stubborn converter which refuses to let you pass EMC/EMI compliance, browns out your MCU, or likes to turn itself into smoke, don’t hesitate to give us a call – we will work with your engineers to implement minimally invasive mitigations to improve converter performance without having to set your progress back with a total clean sheet redesign.

Embedded Systems Design

RedRidge designs a wide range of embedded systems hardware, from ultra low cost 8-bit MCU platforms to high performance FPGA and embedded Linux systems. RedRidge also has extensive experience in the design of embedded user interfaces, including high fidelity displays, capacitive and resistive touch controllers, electromechanical integration for control panels, and human interface ESD/EMI protections.

Successful embedded systems designs require tight integration of the hardware and firmware development process – and hardware-only development firms often produce designs that make the firmware development more difficult than it needs to be. As a full stack product development house, we’re also firmware developers, and we believe that even when we aren’t the ones writing the device firmware, our firmware development expertise greatly enhances our embedded hardware designs. Things like thoughtful grouping of peripheral devices onto serial busses to reduce resource sharing across disparate RTOS threads, careful consideration of the device’s low power modes and needed wake up sources, separation of memories for OTA update / backup images and application data, etc., can all make the life of your firmware team much easier down the road.

We also understand that one of the most valuable things a hardware team can do is to get the firmware team rolling as early as possible in the development process. Our typical approach involves first building up benchtop systems which integrate development kits of the MCU/FPGA, key peripherals, and sensors. These systems allow firmware developers to start working on device drivers and performing integration tests before the first PCB’s have even been built.

Our embedded system design philosophy is focused foremost on testability, both of the hardware itself, and designing the hardware to facilitate in-system firmware testing. That means providing extensive test point coverage, 0-Ohm jumpers for easy separation of subsystems when debugging or troubleshooting boards, and high bandwidth serial interfaces dedicated to in-system production programming and remote procedure call (RCP) firmware unit testing. We believe in designing for test support from day one, and carry powerful test access through to production designs. RedRidge designs every board with the goal of making firmware debugging and test fixture design as easy as possible.

RF & Microwave Electronics Design

RedRidge offers design and simulation services for complex RF and uW designs including solid-state power amplifiers, highspeed ADC/DAC front ends, discrete transceiver implementations, low noise receivers, absorptive filter designs, and more. We have experience designing module-level FPGA mezzanine cards, as well as fully integrated high-level RF systems in the areas of Communications Radios, Radar, GPS/GNSS, Medical Imaging, RFID & NFC, Wireless Power Transfer, Optical Modulator Drives (Acousto/Electro optic), Optical Receivers & Detector Front Ends.

We have extensive experience working in planar waveguides on high performance laminates, including design of distributed structures (filters, bias-tees, matching networks, combiners, etc.), high-bandwidth waveguide transitions, pad/wirebond transitions, and planar antenna implementations. Our experience is all at the board and systems level, ie we don’t do MMIC design, but we have done a number of supporting PCBs for custom MMICs.

We also design a wide variety of high-fidelity supporting electronics such as low noise power supplies (Ultra-high PSRR LDO implementations, slew-rate controlled switching pre-regulators, etc.), bias voltage supplies, automatic gain control (AGC) loops, monitor detectors, baseband signal generation, and more.

Our electronics design lab in Boulder Colorado is well instrumented up to roughly 20 GHz, beyond which we typically rent equipment on a per-project basis.

Design for Manufacturing (DFM)

Those new to product development often assume the first proof of concept system is the hard part, and that once it works, buttoning it up into a product will easy. In practice, proof of concept systems are often trivial compared to the total effort required to bring quality, reliable electronics to commercial production.

Like many things in engineering, DFM optimization can be easy if it’s integrated into the design process from the beginning, or quite time consuming and expensive if it’s done as an afterthought in the final stages of development. Electronics design has a similar dynamic to software development, in that good production practices often actually make prototype development faster.

RedRidge brings the experience of taking hundreds of products through to commercial production, and the lessons learned in the design and optimization of their PCBAs, cable assemblies, mechanical enclosures, packaging, automated test fixtures, and test protocols. If you have an electronics design that’s hitting these issues as you near production, or are starting a clean sheet project and want to address manufacturability from the outset, we’re happy to help.

RedRidge offers DFM design review and modification support for existing electronics designs, as well as sustaining manufacturing support services to address issues that arise over a product’s lifetime such as component shortages, contract manufacturer quality, and cost control.