Our Approach

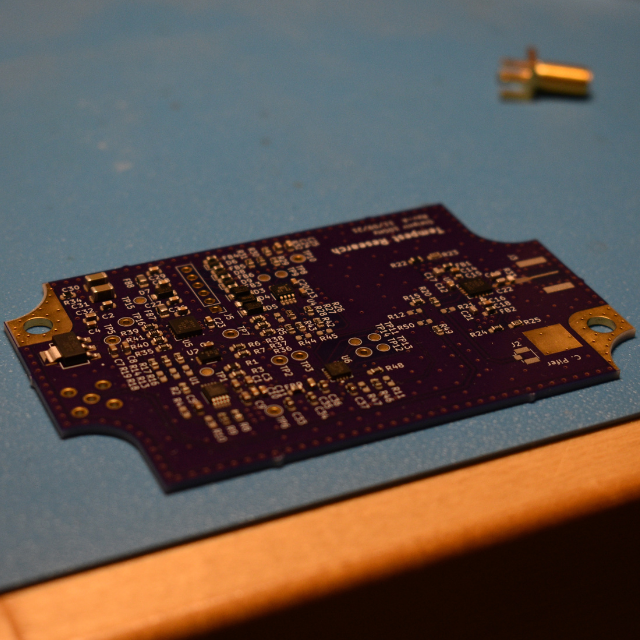

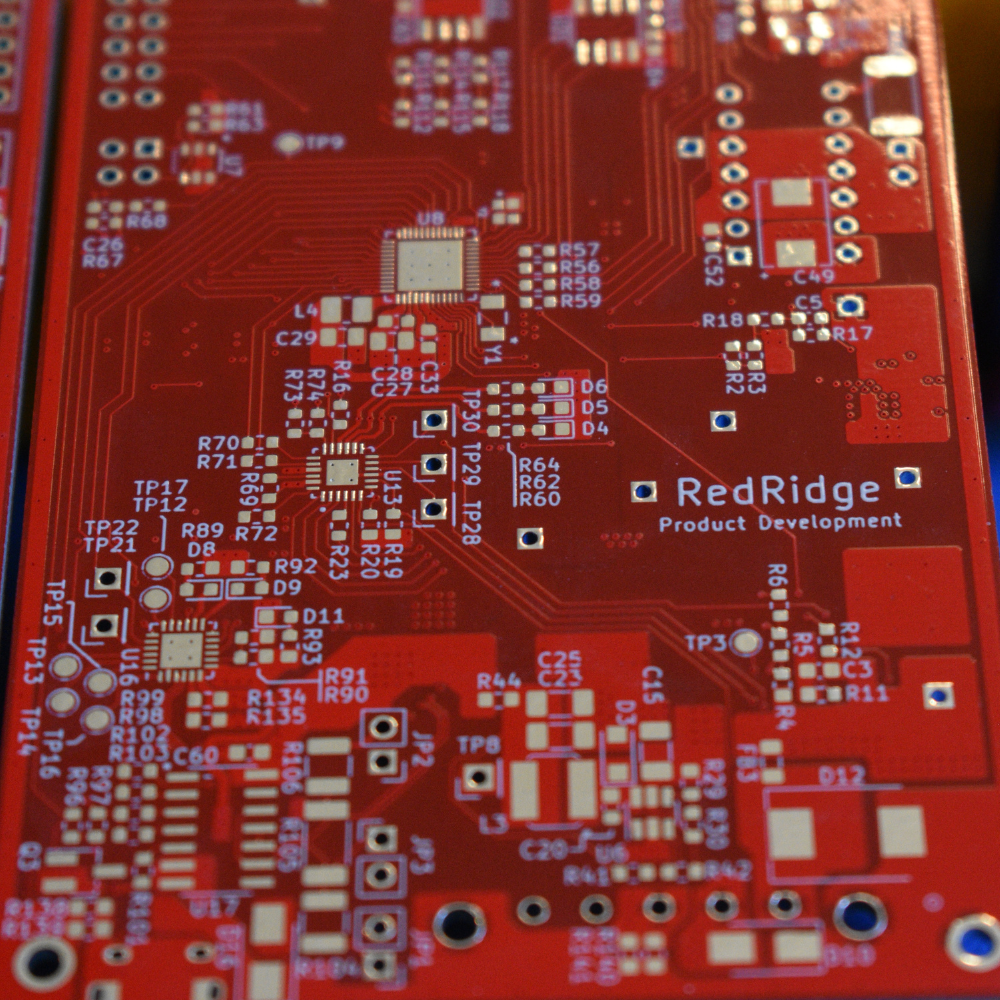

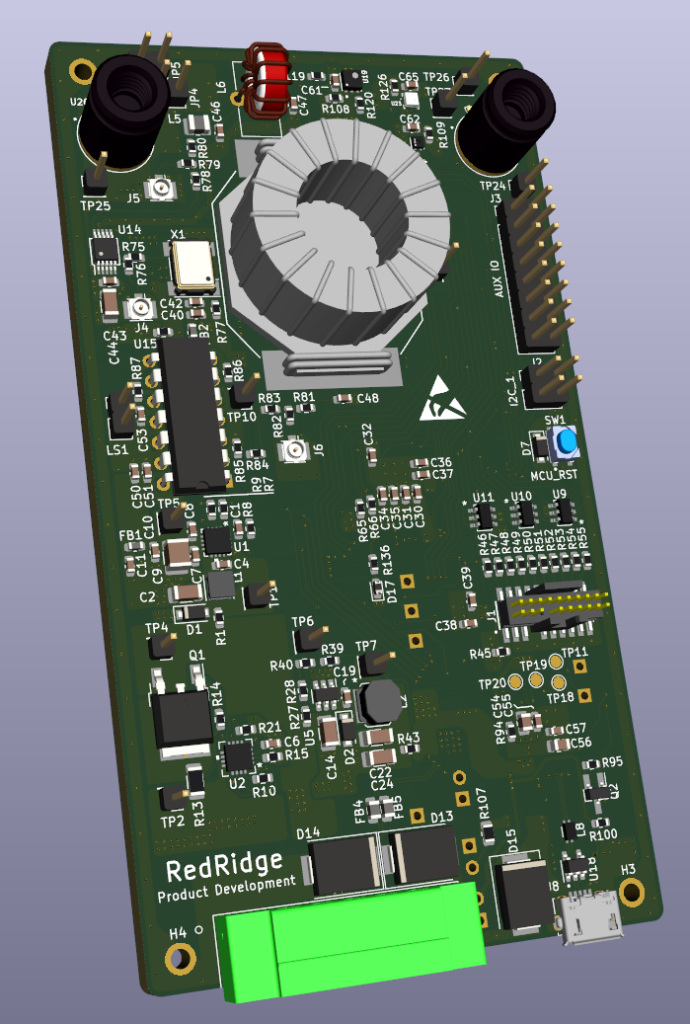

RedRidge offers stand alone Printed Circuit Board (PCB) layout services in Altium Designer, KiCAD EDA, and Autodesk EAGLE. We do all layout work in-house here in Boulder Colorado, and are focused on integrating our layout work into your team’s workflow.

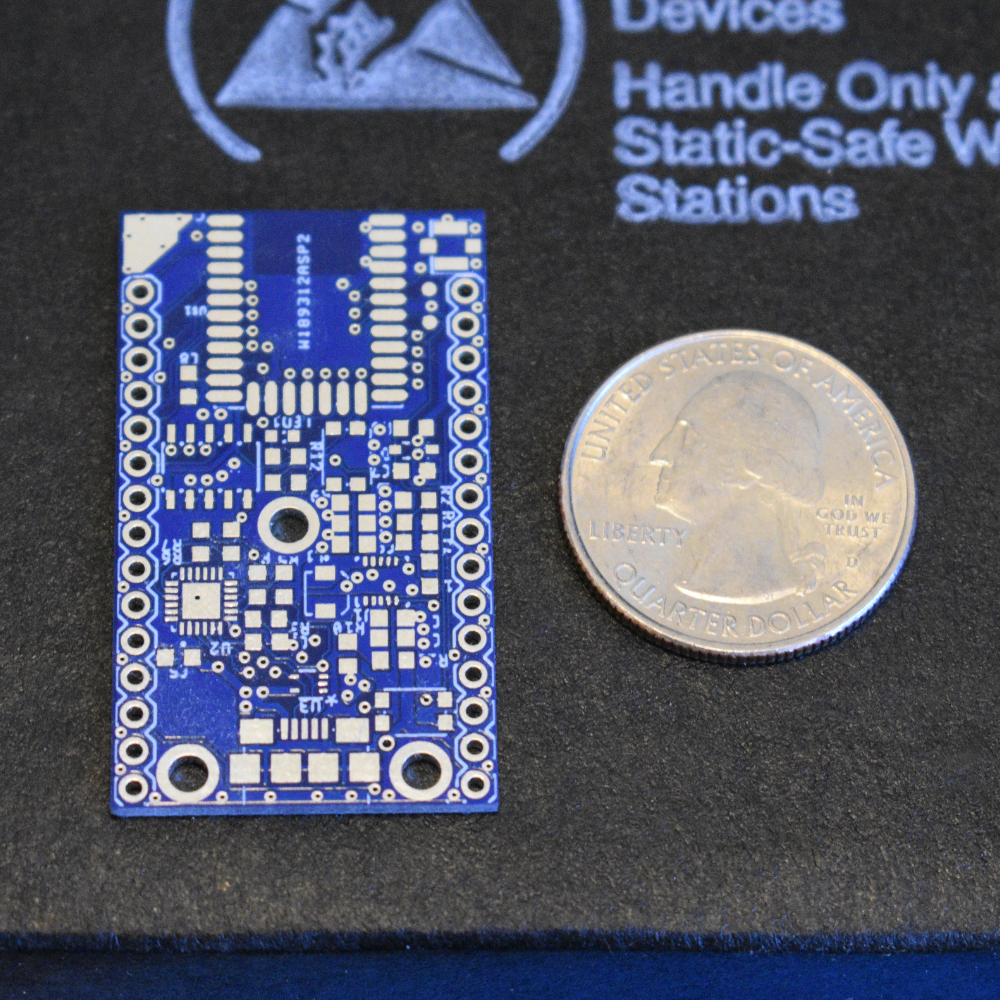

Many layout shops choose to subcontract out work to inexpensive and often offshore CAD technicians, but we have found with the ever increasing complexity and performance requirements of modern board designs, this approach is ultimately more expensive for the client. We have seen instances where these “cheap” layout options become massively expensive and threaten to kill entire projects, as the board is re-spun again and again trying to pass electromagnetic compliance, resolve signal integrity short comings, or fix an underperforming on-board radio. Modern EMI/EMC requirements are stringent, digital interface speeds on video and serial links have increased into the microwave regime, and the pressure for form-factor miniaturization has driven even relatively simple electronics onto higher layer count boards with tight mechanical interfacing.

We have extensive experience laying out PCB’s for challenging applications across the Aerospace, Medical, Scientific, and Consumer Electronics industries. And because we also do complete product design, our layout work benefits from having deep in-house expertise in EMI/EMC testing, Embedded systems engineering, RF & Microwave structures design/simulation, printed antenna design, mechanical engineering co-design, DFM analysis, and production test automation. We also have experience designing boards and electronics for several specialty compliance requirements, such as: MilSpec Aerospace, Down-well Oil & Gas Equipment, Class 1 Division 1 & Class 1 Division 2 Hazardous Location and Explosive Atmosphere Certification, Ultra-low leakage current medical equipment (60601-1 double isolation), automotive & naval vibration testing, and others.

Our philosophy is that PCB design is a critical part of product development, and that the most cost and time effective approach is to leverage experienced design engineers who can sit with your team for design reviews, work closely with mechanical and electrical engineering teams, and handle more technically sophisticated design aspects. If your team leads layout support, but you’ve been skeptical about whether an outside layout resource would understand the challenging aspects of your design, or if you’ve been burned by endless board revisions cycles and EMC troubles in the past, we’d love to show you how we can help. Get in touch for a no-cost consultation & estimate.

Engagement Structures

RedRidge supports engagements on both a fixed-price and time & materials basis, depending on the nature of the project and the preference of the client. For PCB layout projects specifically, if the schematic design is fully finalized, and the mechanical constraints are well defined, we will typically offer bids in either structure. If the schematic design or mechanical constraints are still undergoing major changes, fully scoping the layout effort is difficult, and we may offer only a time & materials bid.

If your design is still in flux, but your company has a strong preference for fixed price contracting, don’t hesitate to give us a call, we can often help firm things up to the point where the layout can be concretely scoped, and we have flexibility to put together a proposal that will work for your project.

Many of our clients prefer fixed-price contracting due to the budgeting certainty it gives them, but there are advantages to both approaches. If for example your company is actively attempting to hire in-house resources to handle board layouts, but it’s going slowly and you’d like someone like us to get the design moving right away, a time & materials engagement gives you maximum flexibility to shuffle design resources around and easily pull the project back in-house partway through if an internal resource becomes available.

Layout Design & Review Process

Our layout process is focused on tight integration and co-development with other development areas, from electrical engineering and schematic capture to mechanical enclosure design. That’s obviously true when RedRidge is also supporting one or more of those efforts in addition to the board layout, but even more importantly it’s still true even when we aren’t.

It doesn’t matter if you’re doing the electronics or mechanical design with us, in-house, or even have a different consulting firm handling it. Our goal is avoid black-boxing the layout work, so we conduct multiple design reviews, open to everyone involved, throughout the project.

Modern improvements to chip configurability such as MCU/FPGA pin & peripheral muxing capabilities have made layout collaboration more valuable than ever before. We’ve found that well coordinated development of IO muxing and connector pinouts can substantially improve EMI performance, and even save whole PCB layers.

We have workflows developed for schematic design collaboration with the Altium 365 platform, as well as with KiCAD + Git. We’re also more than happy to fit into your companies existing workflow.

We’re also big believers in building full 3D modeling of the PCB during the layout phase. With the increased availability of vendor component models, it’s much less work than it used to be – and it offers huge improvements to mechanical design integration. Allowing the mechanical engineer to fit and interference check the complete assembly in 3D CAD prior to PCB fabrication helps ensure first-time-right.

The main steps to a layout project are:

- Mechanical Interface Review

- Manufacturing & PCB Technology Level Assessment

- Component Footprint Creation and Board Placement

- Placement Review

- PCB Routing

- Routing Review

- Mechanical Interface Integration

- Fabrication Package & Board Manufacturing

Beyond PCB Layout – Manufacturing Support

RedRidge offers full manufacturing support for the boards, which includes selecting contract manufacturers to fabricate the PCBA’s, soliciting several competitive manufacturing quotes, handling any change requests from the fab’s CAM review engineer, and supporting the fab with any technical questions which they need answered during assembly.

RedRidge has experience working with many of the PCB assembly shops here in Colorado, and most of the major bare-board manufactures in the US, as well as setting up off-shore manufacturing for high volume builds. Unlike some combination design and manufacturing firms, we’re not tied to any particular PCB manufacturer, so we can help you select a manufacturer that’s well matched to your build volume, turn-time needs, and PCB technology level.

We can also help you plan out your manufacturing strategy across multiple board revisions, which can make your road to volume production much smoother. Typically the best shop to build a quick turn prototype run of 10 units is not the best choice to build a production run of 40 thousand units, and vice-versa.

If your company has experience with PCB ordering/manufacturing and wants to handle these aspects internally, we’re happy to hand off the fabrication package and let you take things from there (and of course we’ll be here if something comes up).